Essential Guide to Installing Your Own Hot Tub

Outline:

– Introduction and why planning matters

– Installation: site assessment, base options, delivery path, and setup workflow

– Plumbing and electrical essentials for safe operation

– Maintenance: water chemistry, cleaning, and energy efficiency

– Conclusion: ownership roadmap and ongoing priorities

Introduction: Why Thoughtful Planning Makes Hot Tub Ownership Rewarding

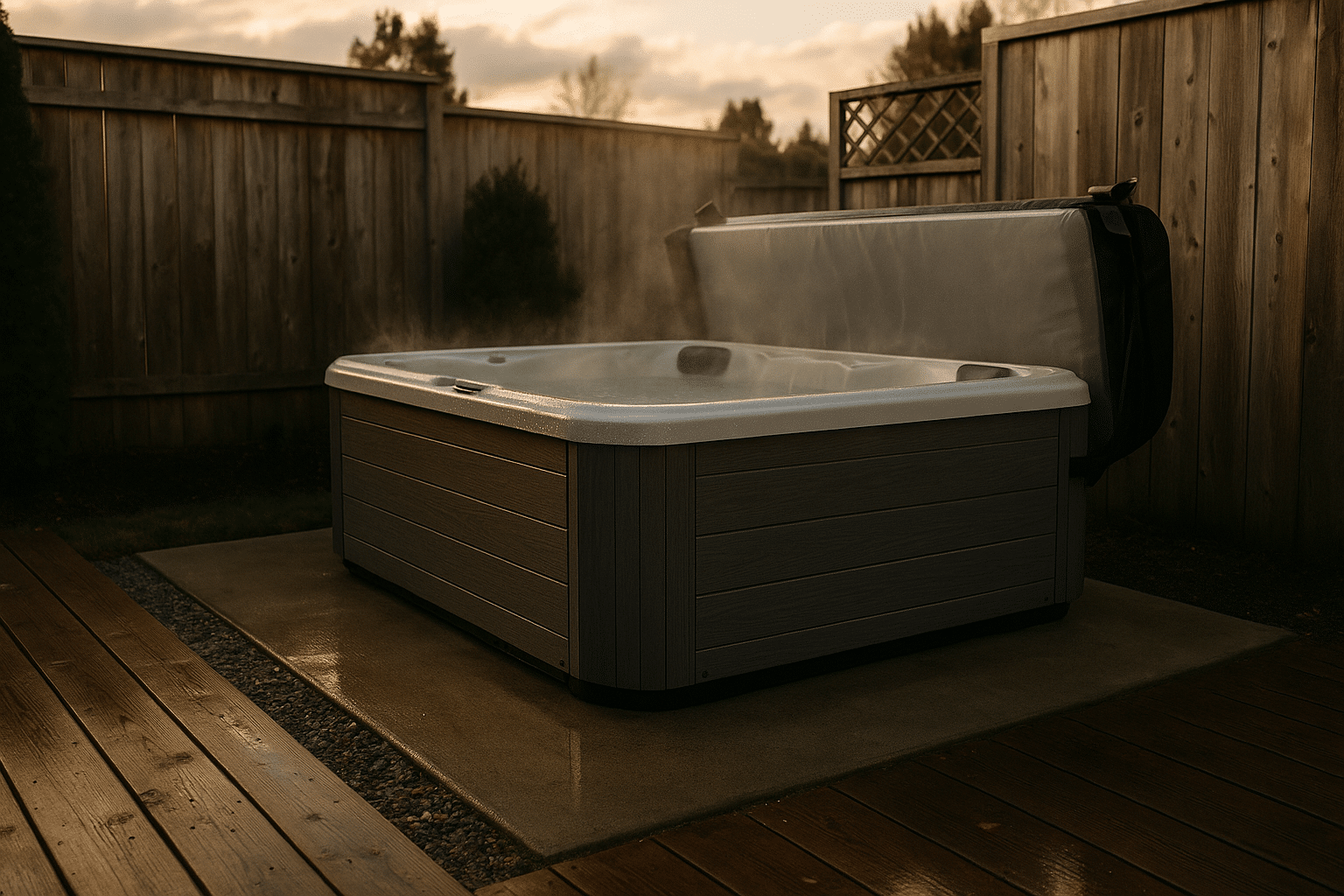

Adding a hot tub can turn a quiet corner of your home into a year‑round retreat, but comfort and reliability begin long before the first swirl of steam. A well‑planned project protects your investment, reduces operating costs, and keeps water clean and comfortable. From a practical standpoint, hot tubs are dense with water, materials, and people: a typical 350–450‑gallon model can weigh 3,000–5,500 pounds when filled and occupied. That weight demands a stable, level base and clear access for service. It also calls for safe, code‑compliant electrical work and thoughtful drainage so you never find standing water under or around the unit after a storm or a routine drain‑and‑refill.

Successful owners tend to think in three layers. First is installation: selecting a location, preparing the base, planning the delivery path, and staging the tub without damage. Second is plumbing and electrical: even if your spa is self‑contained, you still need a reliable water source for fills, a place to drain, frost‑aware routing outdoors, and a dedicated, properly protected electrical circuit. Third is maintenance: stable water chemistry, a clean filtration system, and a tight, insulated cover that locks in heat and keeps debris and sunlight out. Skipping any layer leads to headaches, from error codes to cloudy water to higher‑than‑necessary power bills.

What follows is a roadmap that begins with the ground beneath your feet. You will learn how to choose and build a base that resists settling, how to plan unobstructed delivery routes, how to coordinate electrical and plumbing details without surprises, and how to keep the water inviting with simple routines. Along the way, you will see where DIY steps are reasonable and where a licensed contractor is the safer choice. The goal is straightforward: dependable, low‑stress soaking that fits your space, your climate, and your budget.

Installation: Site Assessment, Base Options, Delivery Path, and Setup Workflow

Great installations start with a site that balances structure, convenience, and privacy. Aim for a location that is close enough to a door to encourage frequent use, yet far enough from bedrooms to avoid pump noise during late cycles. Consider wind exposure and trees; a windbreak reduces heat loss, while overhanging branches mean more debris and more frequent cleaning. Sun patterns matter too: morning light can be pleasant, but strong afternoon sun in summer can raise water temperature faster than you want. Finally, visualize access for service: most hot tubs need 18–24 inches of clearance on the equipment side for panel removal and component replacement.

Base options vary by budget, soil conditions, and permanence. Common choices include a reinforced concrete slab, compacted gravel with pavers, or an engineered deck. A slab offers excellent stability; many owners choose a 4‑inch slab with reinforcement on compacted sub‑base. Pavers over well‑compacted gravel are workable if the ground is properly graded and the pavers remain level under load. Deck installations require structural verification, as filled hot tubs concentrate load; consultation with a qualified professional is prudent to ensure framing, footings, and connections meet the expected live and dead loads. In all cases, target a level surface within 1/8 inch across the footprint, with surrounding grading that moves rainwater away from the area.

Plan the delivery path as carefully as the base. Measure every gate, turn, and overhead obstacle from the street or driveway to the pad. Hot tubs are often delivered on their side with a dolly, and clearances of 40 inches or more may be needed depending on model dimensions and route geometry. Remove trip hazards, secure pets, and protect delicate surfaces. If a crane is required for tight urban yards or elevated decks, coordinate a specific time window, confirm ground conditions for stabilizers, and keep overhead lines in mind.

Once the tub arrives, stage it near the final location, confirm orientation, and set it gently onto the base. Before filling, remove all packaging, confirm that unions and valves in the equipment bay are snug, and ensure any internal slice valves are open. Install the cover lifter if included in your plan; it is easier before the tub is filled. Then proceed to the initial fill using a clean garden hose placed in the filter compartment to help purge air from lines. During the fill, watch for levelness; minor shimming with non‑compressible pads may be warranted if the surface is slightly out. A careful, unrushed installation day pays dividends for years.

Helpful checklist highlights:

– Verify base is level and drains away from the tub area

– Measure every doorway, gate, and turn along the delivery path

– Confirm equipment‑side clearance and cover swing space

– Tighten unions and open slice valves prior to filling

– Place hose in filter well to reduce air pockets during the fill

Plumbing and Electrical Essentials for a Reliable Setup

Although modern hot tubs are self‑contained, plumbing considerations still matter. Your primary water source will be a standard hose bibb; ensure adequate flow and a clean hose, as sediments can cloud the startup. Plan a safe place for draining, whether a lawn area graded away from structures, a landscape bed that can handle the volume, or a floor drain if installing indoors. A 350–450‑gallon drain can release thousands of pounds of water; route it thoughtfully to avoid erosion or nuisance flooding. In cold climates, confirm that exterior drains and hoses remain usable in winter or plan seasonal procedures like a sump pump and discharge hose to a proper outlet.

Inside the equipment bay, familiarize yourself with key components: pump(s), heater, control pack, ozone or UV system if present, and the network of manifolds and jets. Most connections are PVC with unions and gasketed joints designed for service. If you notice a drip at startup, power down, tighten the affected union hand‑tight plus a gentle quarter turn, and let the gasket reseal as temperatures stabilize. Avoid aggressive over‑tightening, which can deform seals. Airlocks sometimes occur after a fresh fill; you may hear a pump hum without moving water. Bleeding air from a union or using purge modes as recommended by the manufacturer typically restores flow quickly.

Electrical planning is central to safety and performance. Many compact models run on 120V circuits, while larger units require dedicated 240V circuits in the 40–60 amp range. Ground‑fault protection is commonly required; a properly rated GFCI helps reduce the risk of shock in wet environments. Conduit, wire sizing, and disconnect placement must respect local codes, distances, and manufacturer specifications. A licensed electrician can route the circuit, set a weather‑resistant disconnect in line of sight, bond metallic components where required, and ensure correct breaker type and wire gauge. Good practice also includes drip loops on conductors, strain reliefs, and careful sealing at penetrations to keep moisture out.

For indoor installations, address condensation and air quality. Warm, humid air should be exhausted gently while preserving heat; balanced ventilation reduces corrosion and mildew. A modest floor drain near the tub simplifies maintenance and spill response, and moisture‑resistant finishes protect surrounding materials. If acoustics matter, vibration‑isolating pads under the cabinet can soften pump noise transmitting through floors. Across all settings, maintain clearances in the equipment bay and keep the area dry; a tidy, ventilated compartment helps electronics live longer and makes troubleshooting much easier.

Quick planning tips:

– Confirm circuit capacity, GFCI protection, and correct wire gauge before delivery

– Choose a reliable drain location and test the route during the first water change

– Label key valves and breakers for fast reference during maintenance

– Keep a basic kit: adjustable wrench, silicone‑safe lubricant, spare filter, test strips

Maintenance: Water Chemistry, Cleaning, and Energy Efficiency

Maintenance is about consistency, not complexity. Once routines are set, clear water and dependable equipment become the norm. Start with chemistry. Typical targets for acrylic hot tubs include pH between 7.2 and 7.8, total alkalinity around 80–120 ppm to buffer pH drift, and calcium hardness in the 150–250 ppm range to protect heaters and reduce foam. Maintain an appropriate sanitizer residual as directed for your chosen system. Test water 2–3 times per week during regular use; small adjustments are easier than big corrections. Shock treatment after heavy use helps oxidize organics that cloud water and consume sanitizer.

Filtration and cleaning keep clarity on track. Rinse the filter with clean water every 1–2 weeks, deep‑clean monthly with a compatible filter solution, and replace annually or as needed based on flow and clarity. Wipe the waterline to prevent scum build‑up, and keep the cover clean inside and out. A quality, well‑fitting cover dramatically reduces evaporation and heat loss; check seals and straps seasonally and replace waterlogged cores when necessary. Many owners change water every 3–4 months, or sooner after frequent gatherings; this interval resets dissolved solids that gradually accumulate despite good care.

Energy efficiency comes from insulation, covers, and habits. Lower standby temperatures slightly when you know you will not soak for several days, but avoid large swings that force long reheats. Keep air controls closed when not in use; air cooling in the jets saps heat quickly. Shield the tub from prevailing winds with fencing or landscaping, and brush snow off the cover in winter to reduce conductive losses. In many climates, monthly energy use varies widely with temperature and soak frequency; thoughtful settings and a tight cover often have the biggest impact.

Seasonal considerations matter. In freezing weather, uninterrupted circulation and heat are your friends. If shutting down for winter, follow a careful sequence: power off, drain fully, blow out lines if recommended, open unions briefly to release trapped water, and leave the cover slightly ajar after cleaning to let moisture dissipate before final closure. In spring, re‑inspect the base for heaving or settling, confirm the GFCI tests properly, and start up with fresh filters and balanced water. Keep simple records of test results and maintenance tasks; trends reveal small changes before they become problems.

Maintenance quick hits:

– Test water a few times weekly and adjust in small steps

– Rinse filters biweekly; deep‑clean monthly; replace roughly yearly

– Keep the cover tight, clean, and undamaged to retain heat

– Change water every 3–4 months or as usage dictates

– Log readings and tasks to spot patterns early

Conclusion: Your Step-by-Step Ownership Roadmap

Owning a hot tub is easier when you view it as a sequence of smart choices, not a single project. Start with a site that respects structure, privacy, and access. Build a base that stays level and dry through the seasons. Plan the delivery route in detail so installation day is calm and predictable. Coordinate electrical and plumbing early, confirm circuit protection, and pick a sensible drain location. Then commit to simple maintenance habits that protect water quality, equipment, and energy use. Each step supports the next, turning a complex system into a low‑stress routine.

If you are planning right now, sketch your space and note the following:

– Base decision: slab, pavers, or engineered deck with verified load capacity

– Access: clear gate widths, tight turns, and crane needs if any

– Power: dedicated circuit, GFCI, and disconnect location in line of sight

– Water: hose fill plan, drain routing, and cold‑weather strategy

– Service: equipment‑side clearance and a storage spot for test kits and supplies

For many homeowners, a balanced approach—DIY on site prep and logistics, licensed pros for electrical and any complex plumbing—delivers reliable results without stretching timelines or budgets. During the first month, test more often, take notes, and get comfortable with adjustments; most owners settle into a rhythm quickly. If something feels off, resist the urge to chase multiple variables at once. Change one thing, observe, then proceed. With a stable base, safe power, thoughtful drainage, and consistent care, your hot tub becomes more than a purchase; it becomes a dependable ritual that fits the way you live, season after season.